Battery FAQ

Can the lead-acid battery compete in

modern times? (BU6)

The answer is YES. Lead-acid is the oldest rechargeable battery in existence.

Invented by the French physician Gaston Planté in 1859, lead-acid was the first

rechargeable battery for commercial use. 150 years later, we still have no

cost-effective alternatives for cars, wheelchairs, scooters, golf carts and UPS

systems. The lead-acid battery has retained a market share in applications

where newer battery chemistries would either be too expensive.

Lead-acid does not lend itself to fast charging. Typical charge time is 8 to 16

hours. A periodic fully saturated charge is essential to prevent sulfation and

the battery must always be stored in a charged state. Leaving the battery in a

discharged condition causes sulfation and a recharge may not be possible.

Finding the ideal charge voltage limit is critical. A high voltage (above

2.40V/cell) produces good battery performance but shortens the service life due

to grid corrosion on the positive plate. A low voltage limit is subject to

sulfation on the negative plate. Leaving the battery on float charge for a

prolonged time does not cause damage.

Lead-acid does not like deep cycling. A full discharge causes extra strain and

each cycle robs the battery of some service life. This wear-down characteristic

also applies to other battery chemistries in varying degrees. To prevent the

battery from being stressed through repetitive deep discharge, a larger battery

is recommended. Lead-acid is inexpensive but the operational costs can be

higher than a nickel-based system if repetitive full cycles are required.

Depending on the depth of discharge and

operating temperature, the sealed lead-acid provides 200 to 300

discharge/charge cycles. The

primary reason for its relatively short cycle life is grid corrosion of the

positive electrode, depletion of the active material and expansion of the

positive plates. These changes are most prevalent at higher operating

temperatures. Cycling does not prevent or reverse the trend.

The lead-acid battery has one of the lowest energy densities, making it

unsuitable for portable devices. In addition, the performance at low

temperatures is marginal. The self-discharge is about 40% per year, one of the

best on rechargeable batteries. In comparison, nickel-cadmium self-discharges

this amount in three months. The high lead content makes the lead-acid

environmentally unfriendly.

Plate thickness

The service life of a lead-acid battery can, in part, be measured by the

thickness of the positive plates. The thicker the plates, the longer the life

will be. During charging and discharging, the lead on the plates gets gradually

eaten away and the sediment falls to the bottom. The weight of a battery is a

good indication of the lead content and the life expectancy.

The plates of automotive starter batteries are about 0.040" (1mm) thick,

while the typical golf cart battery will have plates that are between

0.07-0.11" (1.8- 2.8mm) thick. Forklift batteries may have plates that

exceed 0.250" (6mm). Most industrial flooded deep-cycle batteries use

lead-antimony plates. This improves the plate life but increases gassing and

water loss.

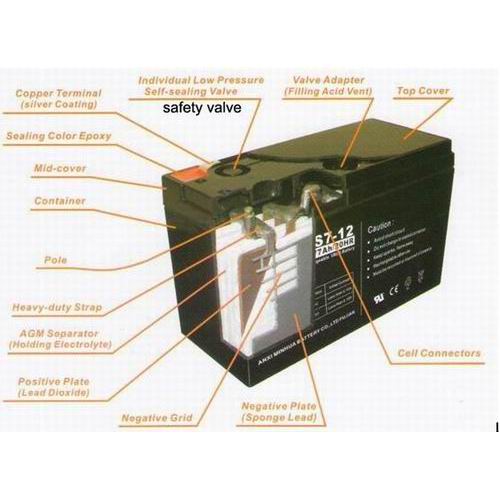

Sealed lead-acid

During the mid 1970s, researchers developed a maintenance-free lead-acid

battery that can operate in any position. The liquid electrolyte is gelled into

moistened separators and the enclosure is sealed. Safety valves allow venting

during charge, discharge and atmospheric pressure changes.

Driven by different market needs, two lead-acid systems emerged: The small

sealed lead-acid (SLA), also known under the

brand name of Gelcell, and the larger Valve-regulated-lead-acid (VRLA). Both

batteries are similar. Engineers may argue that the word 'sealed lead-acid' is

a misnomer because no rechargeable battery can be totally sealed.

Unlike the flooded lead-acid battery, bothSLAand VRLA are designed with a low over-voltage

potential to prohibit the battery from reaching its gas-generating potential

during charge because excess charging would cause gassing and water depletion.

Consequently, these batteries can never be charged to their full potential. To

reduce dry-out, sealed lead-acid batteries use lead-calcium instead of the

lead-antimony.

The optimum operating temperature for the lead-acid battery is 25*C (77*F). Elevated

temperature reduces longevity. As a guideline, every 8?C (15*F) rise in

temperature will cut the battery life in half. A VRLA, which would last for 10 years at 25*C (77*F),

will only be good for 5 years if operated at 33*C (95*F). Theoretically the

same battery would last a little more than one year at a desert temperature of

42*C (107*F).

The sealed lead-acid battery is rated at a 5-hour (0.2)

and 20-hour (0.05C) discharge. Longer discharge times produce higher capacity

readings because of lower losses. The lead-acid performs well on high load

currents.

Absorbed Glass Mat Batteries (AGM)

The AGM is a newer type sealed lead-acid that uses absorbed glass mats between

the plates. It is sealed, maintenance-free and the plates are rigidly mounted

to withstand extensive shock and vibration. Nearly all AGM batteries are

recombinant, meaning they can recombine 99% of the oxygen and hydrogen. There

is almost no water is loss.

The charging voltages are the same as for other lead-acid batteries. Even under

severe overcharge conditions, hydrogen emission is below the 4% specified for

aircraft and enclosed spaces. The low self-discharge of 1-3% per month allows

long storage before recharging. The AGM costs twice that of the flooded version

of the same capacity. Because of durability, German high performance cars use

AGM batteries in favor of the flooded type.

Advantages

- Inexpensive and simple to manufacture.

- Mature, reliable and well-understood technology - when used correctly, lead-acid is durable and provides dependable service.

- The self-discharge is among the lowest of rechargeable battery systems.

- Capable of high discharge rates.

Limitations

- Low energy density - poor weight-to-energy ratio limits use to stationary and wheeled applications.

- Cannot be stored in a discharged condition - the cell voltage should never drop below 2.10V.

- Allows only a limited number of full discharge cycles - well suited for standby applications that require only occasional deep discharges.

- lead content and electrolyte make the battery environmentally unfriendly.

- Transportation restrictions on flooded lead acid - there are environmental concerns regarding spillage.

- Thermal runaway can occur if improperly charged.

CATEGORIES

LATEST NEWS

CONTACT US

Contact:

Phone: 86-18202083776

Tel:

Email: sales@mingepower.cn

Add:

Angela

Angela